Electrical Problems

CAN ELECTRICAL FIRES BE PREVENTED?

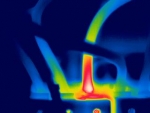

With infrared scanning technology, potentially dangerous heat that normally can’t be seen is easily identified.

How a Thermographer Can Help

Many facility managers still refer to Thermographers as the men with their “Magic Box” that is supposed to find everything. The onsite professionals often scoff at the idea that a Thermographer can come into their facility and find issues that they don’t know about.

“How can a thermographer find issues with our equipment that we work with everyday and know so well?”

The truth is that the Thermographer provides a road map to help the facility managers, electrical engineers, and electricians do their jobs that much better. Let me share a perfect example of how infrared thermography can help identify an electrical hazard.

How It Works

What an Electrician Sees

What an Infrared Camera Sees

Infrared Experiment

Imagine being an onsite electrician and opening one of several electrical panels like the one above. You see a circuit breaker that shows no visible problems. As the onsite electrician, I am certain that you would close back up the panel and think that there was nothing wrong.

The infrared camera shows a different story.

A quick scan shows an alarming glow from just one of the conductors on the upper side of the 3-phase circuit breaker.

Nothing was visible to the naked eye, yet this was a potential fire hazard that most likely would have gone unidentified until flames were blazing.

Thermographers Identify Potential Issues

Once the issue is identified, the onsite electrician can start their troubleshooting process. With the above breaker, they would probably start by tightening the securing lug on the breaker to see if it was responsible for the apparent poor overheated connection.

I was not part of the repair process on the above breaker. Whether this was a sign of a poor connection, oxidation, a bad circuit breaker, or out of phase wiring, I do not know.

As a Thermographer, I was able to identify the overheated condition, and the repair was left to the professionals that were familiar with the building’s equipment and systems.

Road Map

Thermographers are not hired to step on the toes of the electrical professionals involved with the building.

Instead, Thermographers are hired to scan the electrical system and prepare a road map report that will help the electrical professionals better maintain the electrical systems being used.

As Thermographers, our skills with infrared help the electrical professionals keep the systems online and running. Remember, downtime is expensive to every business. And we can help prevent downtime.

Post Repair Evaluations

Once the repair is made by the onsite personnel, it is advised that the Thermographer re-scan the components to ensure that the issue has been resolved.

Hired Repairmen Post Evaluations

Many facilities do not have repair electricians and electrical engineers on staff. Instead, they have to hire repair professionals to resolve the issues identified during the infrared scan process.

Before paying a repair invoice, it is prudent to have the components re-scanned by the Thermographer to ensure that the repairs made actually resolved the identified issues.

All Electrical Components Can Be Scanned

Virtually any electrical component can be surveyed with an infrared camera.

Stop and think about all of the electrical components in your business, facility, building, and home. Now think about the damage caused by fires in these same structures.

The electrical fire damage is usually small compared to the major flood damage caused by the water from the fire hoses that is used to put out the flames.

Infrared scanning should be included in your property’s preventive maintenance program.